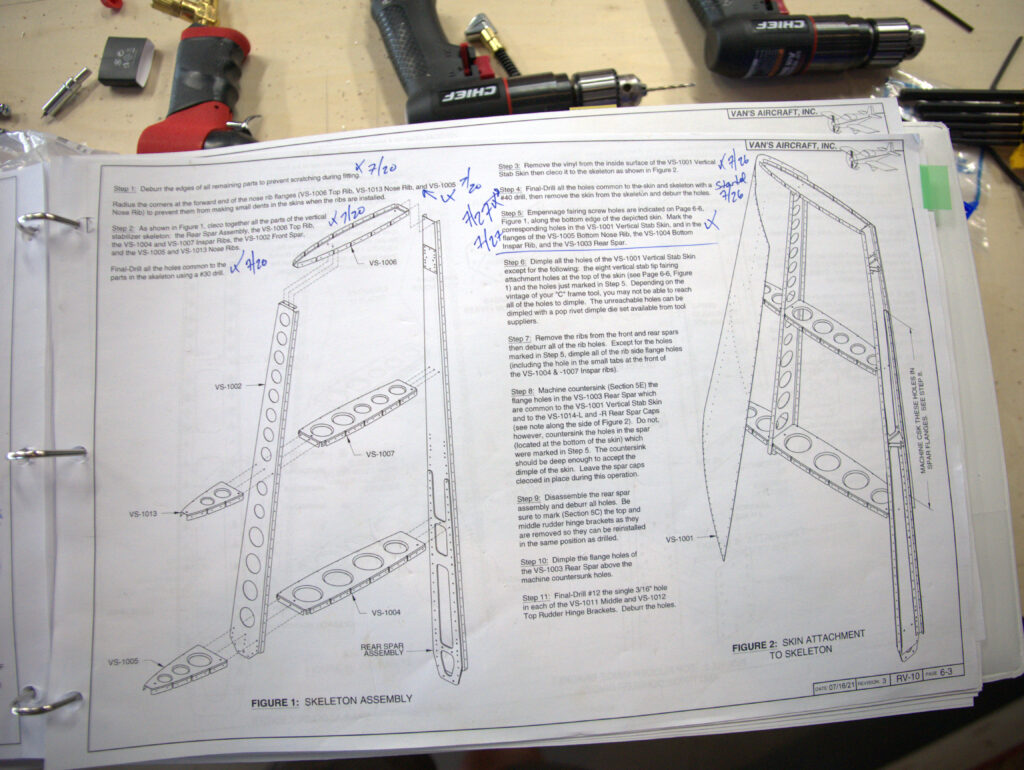

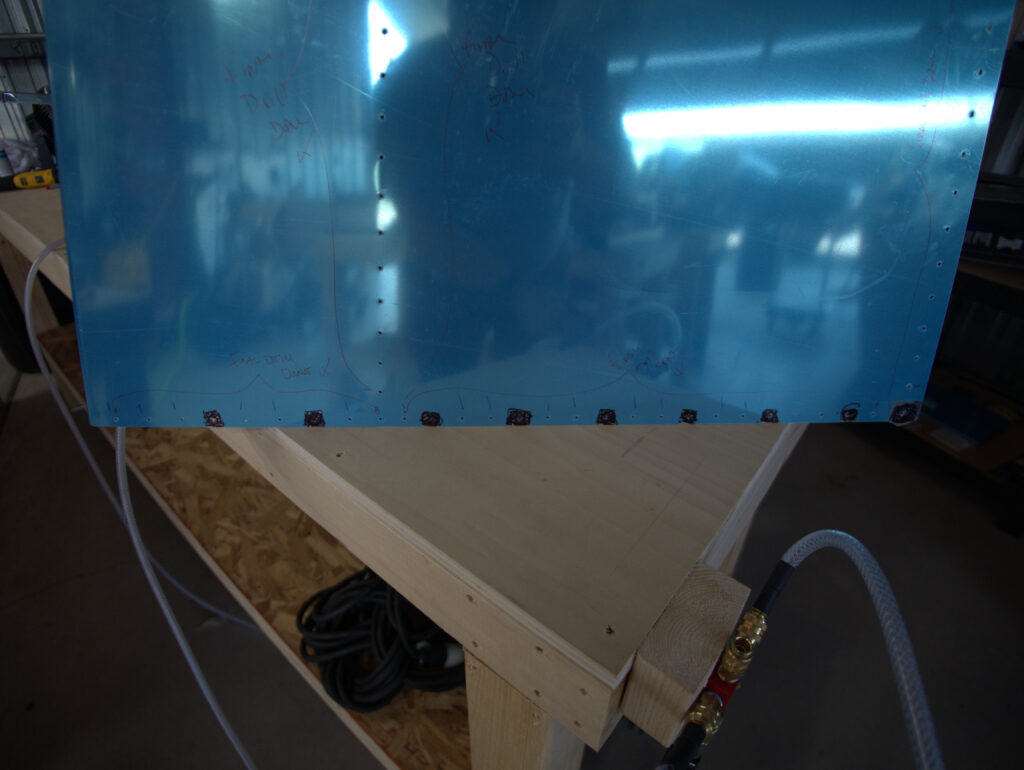

Work is progressing on the vertical stabilizer. I completed the final drilling step along with step 5 for marking the faring screw holes so that they don’t get dimpled or riveted.

I’ve watched some videos on YT where the builder used tape to mark the holes. I think I should have done this instead. I am finding that my work methods are improving quickly but I need to spend more time preparing for the tasks that I will be doing in advance.

Another lesson learned is that the skin can go on going from one side to another. I was under the impression that it had to be stretched. I plan to try this before I start the riveting step. Speaking of next steps. My next step is to start dimpling the skin (VS-1001) and then dimple the skeleton. Once dimpled, I will disassemble and prime the parts before I reassemble them and then rivet.

I am taking a few days off to celebrate a very important wedding in my family. My son is getting married on August 2nd in Cazenovia, NY. His bride is a lovely person, whom we have known since they met in college at LeMoyne University. I believe they met their freshman year but it might be in their sophomore year when they met.

Once the wedding is over I have to get ready to receive the Fuselog kit that Van’s shipped out about a week ago. I will try to take pictures and possibly some video. I have the Empennage, Wing, and Finish kits already. I also purchased the extended wing kit from Sky Designs. I have not received the engine, prop, or avionics yet.