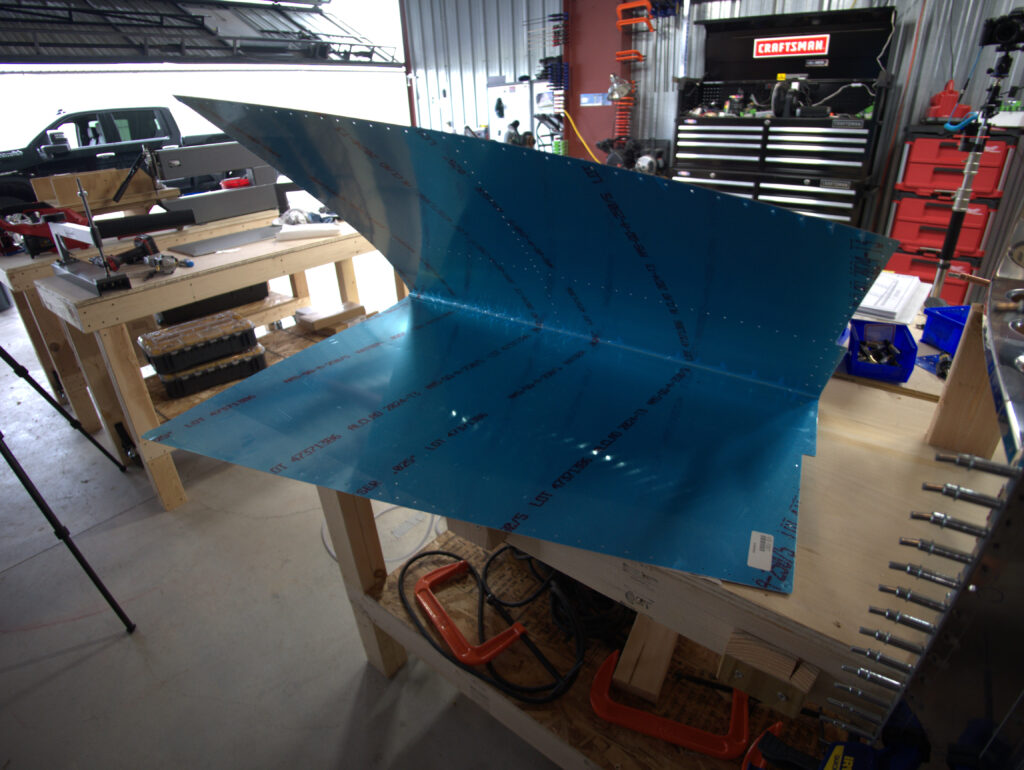

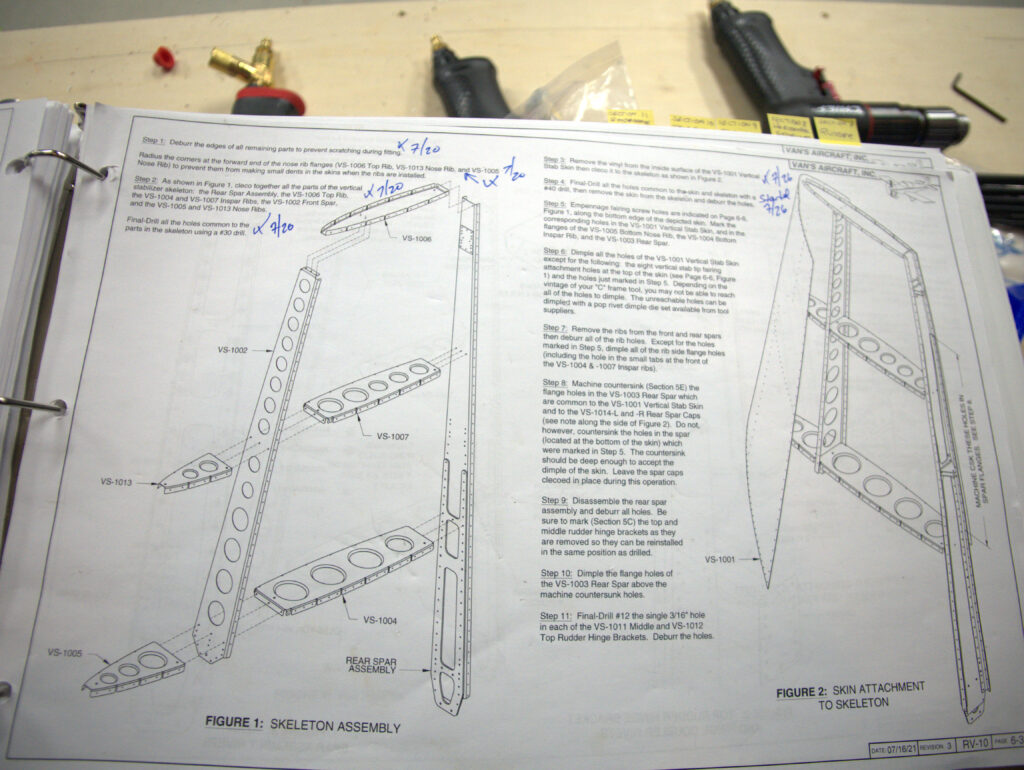

Continued work on Section 6-3, Skin on skeleton attachment. This took a lot more time than I expected. The skin (VS-1001) has to be cleco’d over the skeleton but getting it aligned is very fiddly and a bit tricky. This is done so that the holes can be final drilled with a #40 bit in preparation for riveting. I was able to get the skin fully cleco’d on the skeleton and final drilling started. Once that is done the skin will be removed, all holes deburred, and then the skin will be dimpled in prep for riveting. It is at this time that I will prime the parts before final assembly.

I started by clamping the skeleton to the workbench. In theory, this should have worked fine, and in the end it ultimately did but I had to us a step ladder to cleco the upper holes.

It was easy to locate the skin, part number: VS-1001. However it is a little difficult to handle, especially when trying to start the cleco task in the first few holes.

The inner skeleton becomes misaligned when the skin is attached. This is something to keep in mind and It might make sense to remove the bottom part VS-1013 when reattaching the skin after the holes are deburred and the skin is dimpled.

I finally got the skin on and started final drilling with a #40 drill. Once I finish the drilling, I will need to remove the skin, debur all of the holes and then dimple the skin in preparation for riveting. I will add a step before I reattach the skin and that will be to prime the parts.

Time on today’s activity: 4hrs

Total time on Section 6/Vertical Stabilizer to date: 20.75 hours