Countersinking, Assembly of skeleton

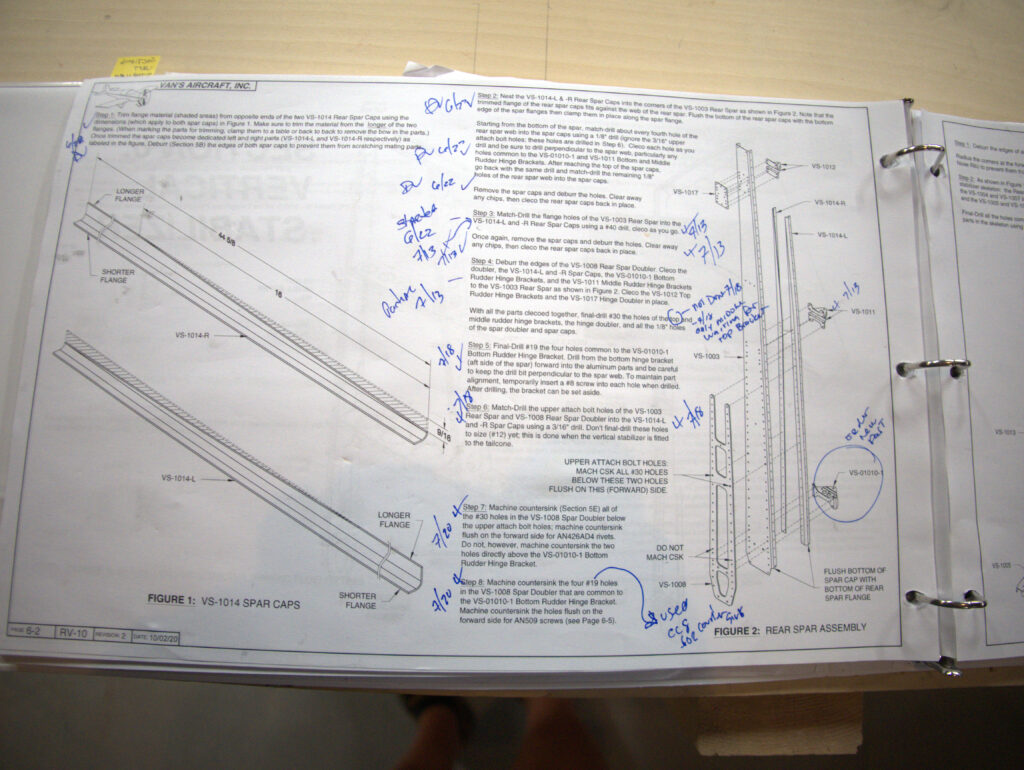

Most of the drilling and deburring work is complete. Final steps were to machine counter sink the #30 holes below the connect holes on VS-1008. Since this was the first time that I have done any machine countersinking, I did quite a bit of practicing.

Then I performed the machine countersinking on the VS-1008 and I am pleased with the results. I tested each countersink with by dropping a rivet in the hole to test if it was flush. I did the same process with the four #19 holes that are for the rudder hinge bracket. The #19 holes are for screws. I did not have a #19 countersink cutter but I matched up a #6 Countersink Cutter and it worked very well.

There is only one task left to do on this page and that is because I had to order a new part that I don’t think that I received with my shipment. I am unable to find VS-1017, nor did I record that I received it in my inventory process. Note to anyone reading this blog post, I cannot understate the importance doing a proper and robust inventory. Not only counting and verifying the parts but also recording the location at where they are stored.

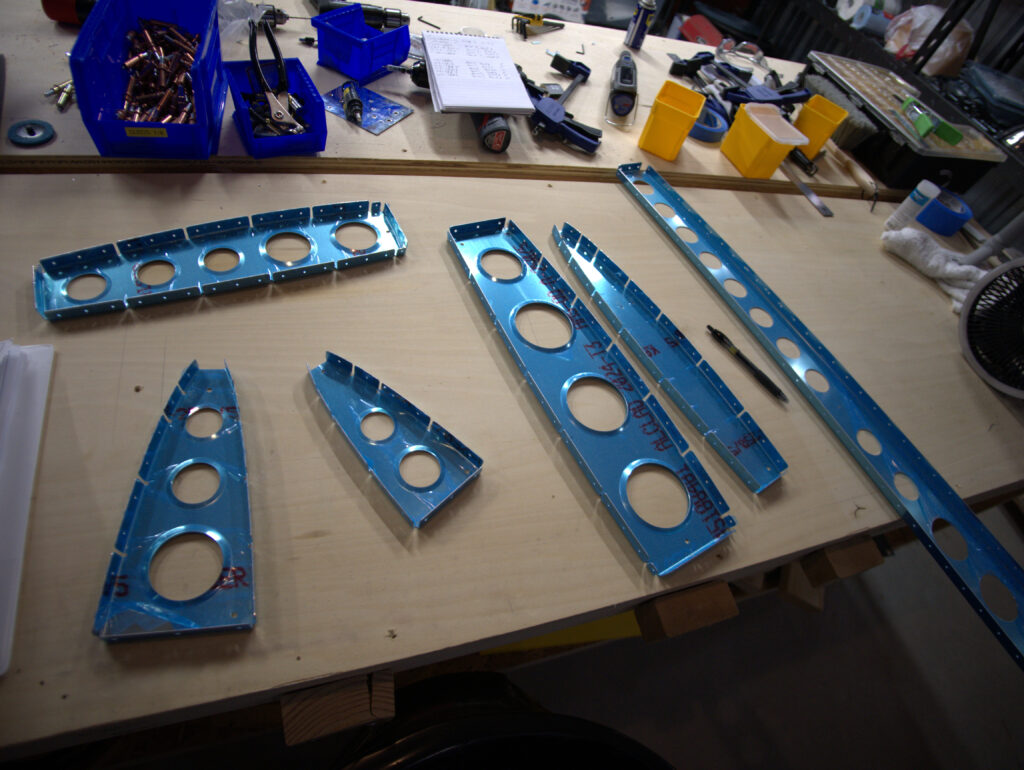

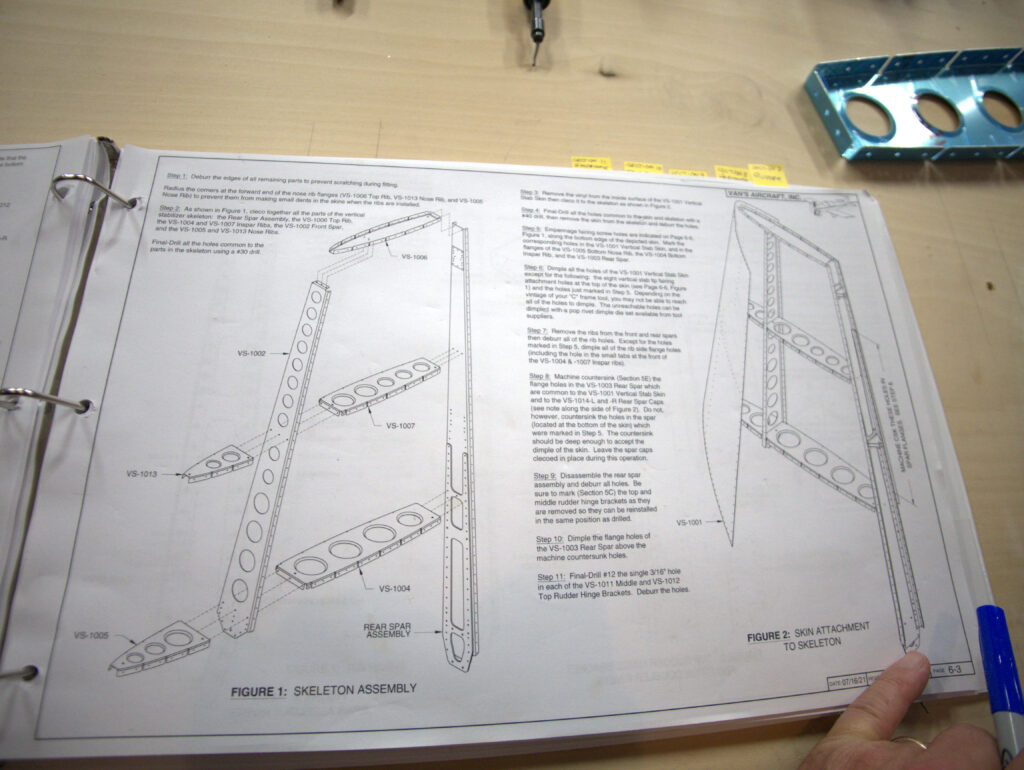

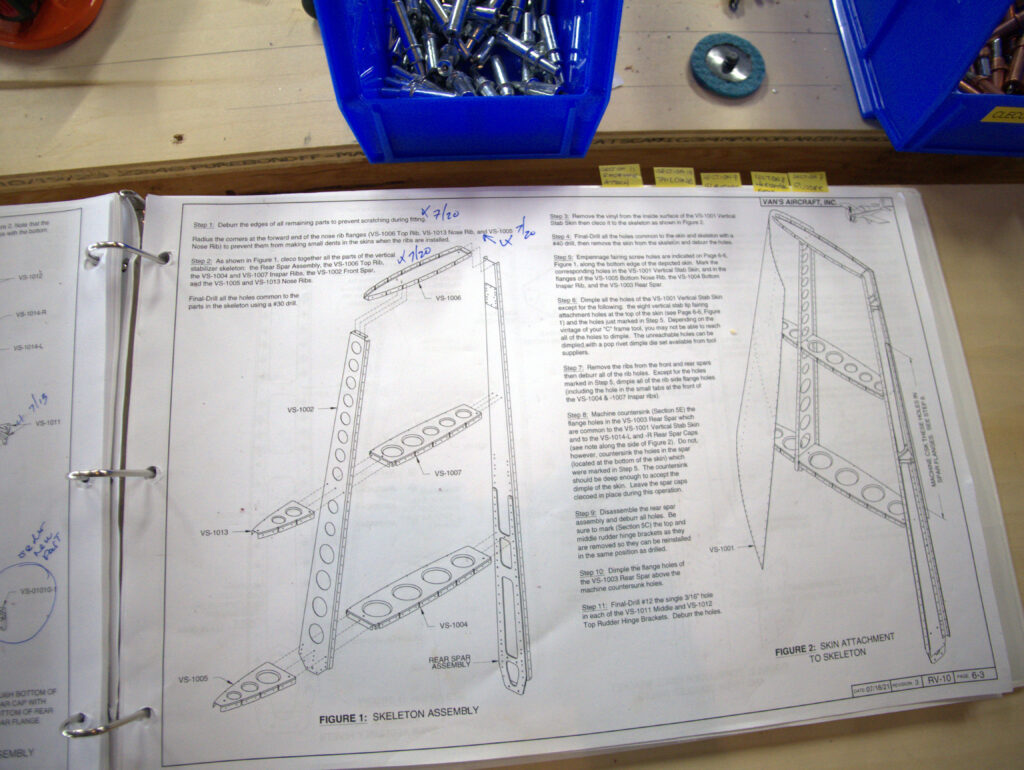

With most of the work complete on the rear spar, I moved onto the next page, 6-3 that focuses mostly on the assembly of the vertical stabilizer skeleton. Again about doing a proper inventory. I kept a spreadsheet with all of the parts and the shelve location that I stored them. I received these parts in October of 2023 and it only took me 5 min to pull these parts using my spreadsheet.

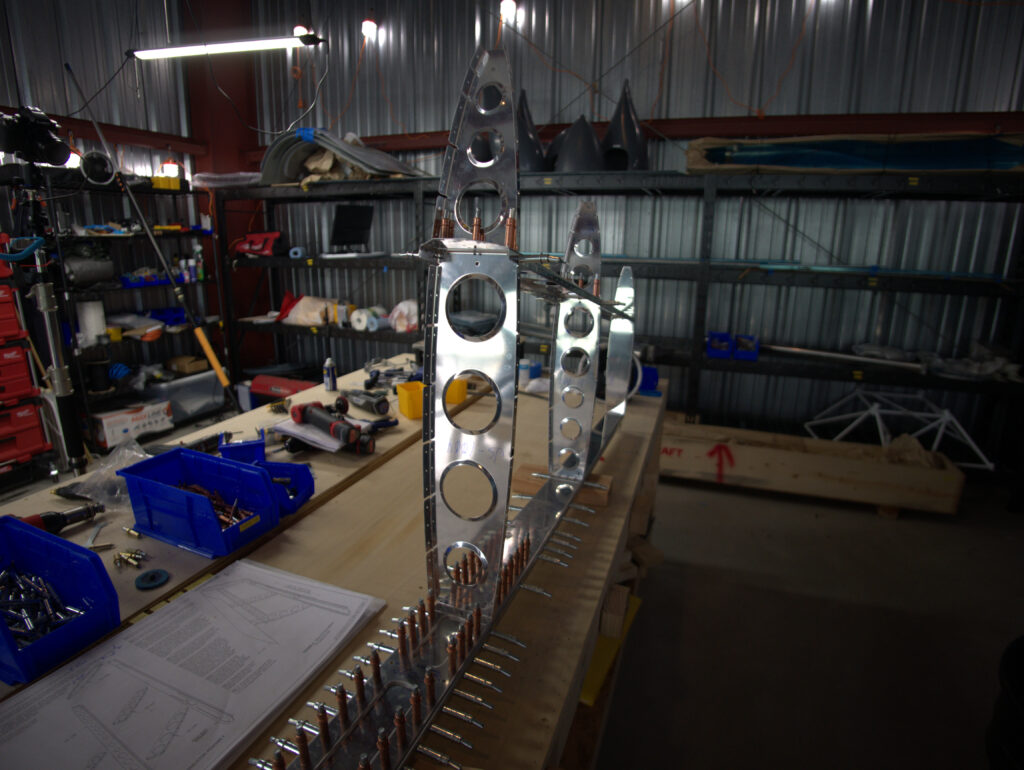

The work on this page was pretty straightforward. I had to deburr all of the edges as to not scratch during fitting, I had to radius the corners of VS-1005 and VS-1013. Once this was complete, I assembled and cleco’d according to the instructions

- Log of build time for 20 July 2025: 5 hours

- Log of build time for the Vertical Stabilizer: 13.72

- Section 6, 6-2 and 6-3

- Next tasks, final drilling of connecting holes.